- Savage Blog

- Accuracy Perfected: How Savage Barrels Are Made

Accuracy Perfected: How Savage Barrels Are Made

Out-of-the-box, accurate rifles. It’s what we’re most known for here at Savage. While there are lots of parts and pieces that go into making an accurate rifle, none are more important than the barrel. We’ve refined and perfected our technique over the last 130+ years to bring hunters and shooters accurate rifles that they can depend on. Each one of our rifles starts with a carefully honed process that transforms raw steel into a barrel built for precision.

At every stage of the process, the goal is simple: produce a barrel capable of delivering the kind of accuracy Savage shooters expect. No shortcuts are taken because precision starts long before a rifle ever reaches the range. From premium materials to hand-fitting and straightening, we’ll take you for a deeper look inside at what sets Savage barrels apart from the competition.

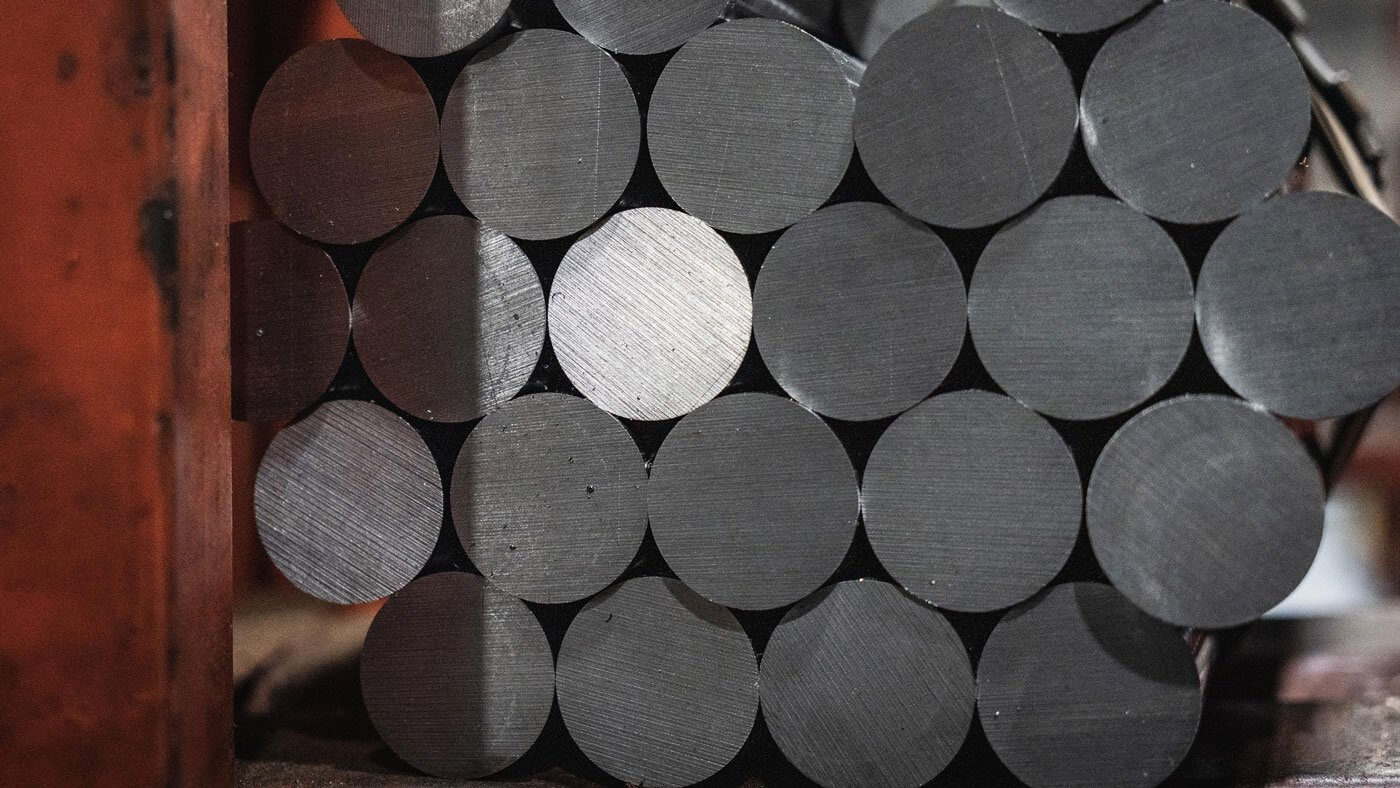

Premium Materials

Savage barrels start their life as high-quality, American-made steel, crafted with precision from the very beginning. There are two main types of steel used in Savage barrels: carbon steel and stainless steel. Carbon steel is the industry standard, often seen with a black oxide, or blued, finish for increased durability and corrosion resistance. Stainless steel is used on more premium rifles, and these barrels offer a higher level of corrosion resistance and better heat management than standard carbon steel barrels.

On select rimfire rifles, we also manufacture in-house carbon fiber-wrapped stainless steel barrels. These barrels maintain the qualities of a stainless steel barrel, but require less material while maintaining the same strength, helping to make the rifles that use these barrels lighter weight.

Drilling and Reaming

The barrel-making process at Savage begins with careful attention to the most critical internal feature: the bore. Each barrel blank is first cut to length, then precision-drilled to create a centered bore that runs true from end to end. This step is critical because any deviation here can compromise the barrel’s performance. That’s why the drilling process is deliberate and closely monitored, ensuring proper alignment and consistency.

Once the bore is drilled, it’s reamed to a specific diameter, smoothing out tool marks and refining the internal surface. This step not only improves dimensional accuracy but also prepares the bore for rifling. A well-reamed bore means better bullet engagement, more consistent velocities, and ultimately tighter groups downrange. Throughout this phase, we check tolerances repeatedly, knowing that even thousandths of an inch can make the difference between average and exceptional.

Button Rifling

Over the years, we’ve learned that if you want the most accurate barrel you can get, your rifling needs to be consistent throughout the bore. Savage barrels are made with button rifling, a process that we’ve refined and mastered to get the most consistency in each barrel.

Select Savage barrels also include an 11-degree target crown that is cut in during the machining process. This crown is ideal for helping to ensure that the circumference of the base of a bullet exits the muzzle at exactly the same time as the gases, improving the rifle’s accuracy. If the crown is not cut properly, or it’s nonexistent, propellant gas will escape on one side of the bullet while the other remains engaged within the bore, resulting in a barrel that is consistently inaccurate.

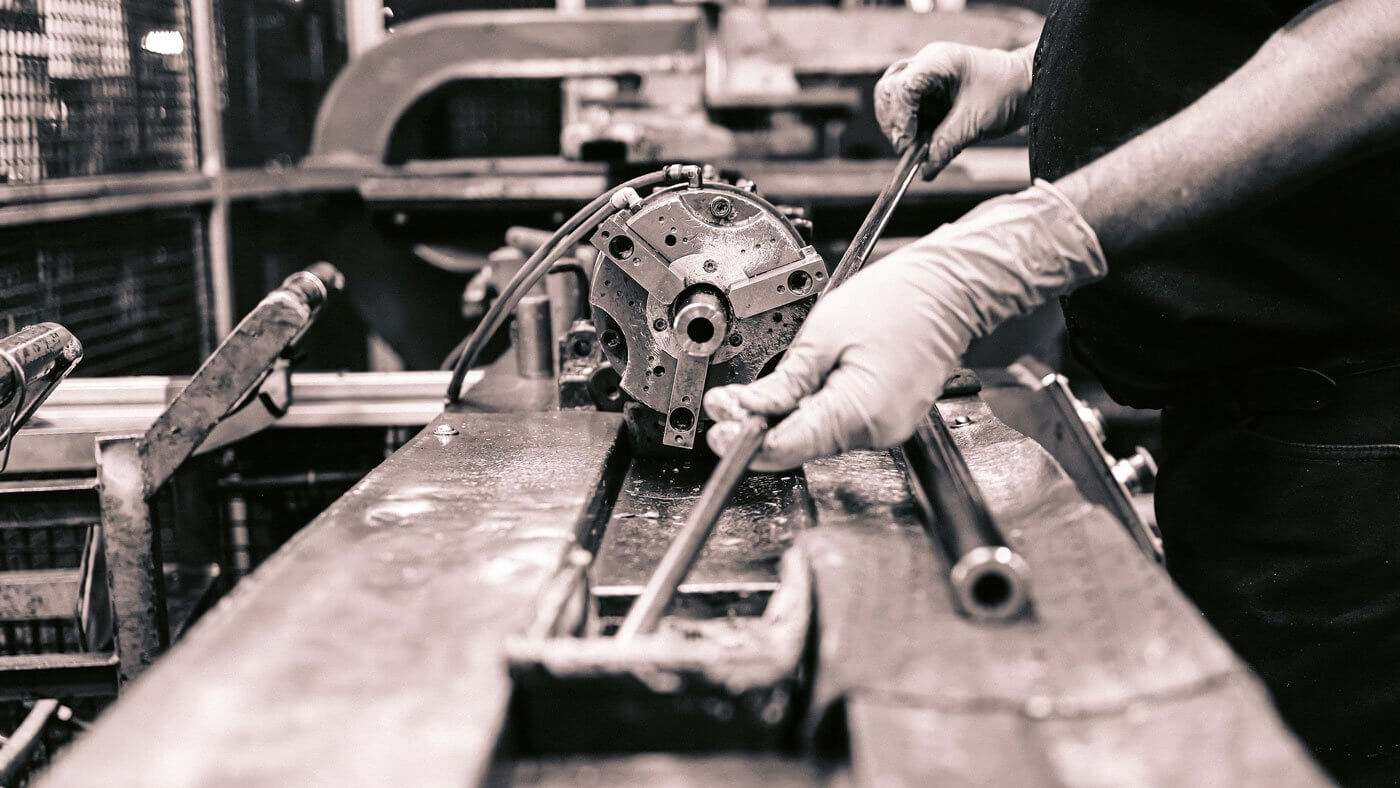

Contour and Turning

Once rifling is complete, the barrel moves into the finishing phase. One of the key steps here is turning the exterior to its final contour. This isn’t just about aesthetics—barrel contour directly affects weight, balance, and how the rifle handles under real-world conditions.

During the turning process, the barrel is secured and spun at high speed while cutting tools remove material in controlled passes. Precision is critical—diameters and tapers must meet tight tolerances not only for performance but also for proper fit with stocks and barrel nuts. Savage technicians inspect the dimensions throughout this step, ensuring consistency across every run. Even minor inconsistencies here could lead to balance issues or stress points that affect long-term accuracy.

If the design calls for it, threading is added to the muzzle for suppressors or brakes. This is done at the same time that the barrel is threaded to fit the receiver, and as the barrel is crowned.

These combined efforts in barrel turning and finishing are a key part of what gives a Savage rifle its reliable, repeatable accuracy, straight from the factory.

Hand Straightened, Every Time

The goal with every shot is to shoot straight, and Savage barrels help ensure you shoot straight every time. Each barrel is checked and straightened before it is fitted to an action and stock, ensuring that there are no defects that would impact your accuracy while shooting.

The straightening process is done by hand using a simple, time-tested process that Savage has used for decades. Our experienced operators are highly trained to look for geometric inconsistencies in every barrel, and they can easily spot if a bore is not perfectly straight. After each barrel is carefully inspected and checked by hand, and any minor adjustments are made to help make the barrel perfectly straight, the chamber is cut in the barrel. The chamber is cut following a precise 3D cast that is made of the chamber, which helps our operators check for and correct any imperfections left over from the machining process.

Savage barrels are cut, rifled, crowned, and finished by a skilled team of craftsmen who are some of the best in the industry at creating accurate, precise rifles. The processes we have perfected over the last 130+ years have resulted in accuracy you’d expect from a custom shop, direct from the factory to your hands. When you’re looking for the most accurate barrels in the industry, look no further than Savage.